Smart Data Center

Leveraging its industry advantages and years of experience in scenario implementation, Nanweiport accurately identifies pain points in data center operation and maintenance inspections. To address the challenges of inspection high inspection frequency numerous inspection points,and poor inspection quality,Nanweiport has introduced the Smart Data Center Inspection Solution.

Primary Feature 01

Primary Feature 02

Equipment Inspection

- In inspection mode, the operational status of components such as indicators,dashboards,digital meters,swiches, etc., on local servers,air conditioners,distribution cabinets,and other equipment can be monitored in real-time 24/7. Combined with proprietary image recognition algorithms, the system identifies and alerts on equipment statuses, truly achieving unmanned operation.

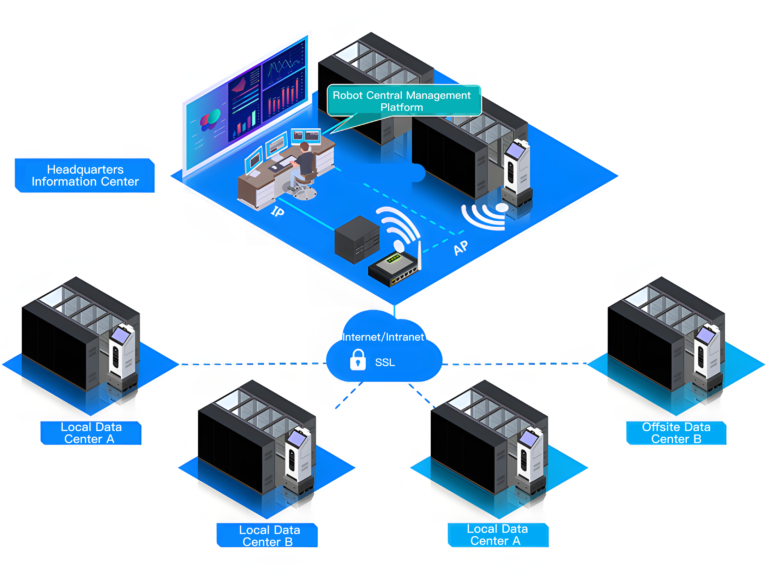

- Users can customize inspection frequencies,timing,and responses to interruptions during inspections customize inspection frequencies, timing, and responses to interruptions during inspections based on their daily inspection needs using the routine inspection strategy function in the robot centralized management platform. They can also extend daily inspection plans to longer automatic execution plans, allowing robots to automatically perform daily data center inspection tasks according to the plan, thus increasing inspection frequency and coverage.

Environmental Monitoring

Real-time Display of Production Dynamics

Noise Monitoring

Odor Detection

Air Quality Monitoring

Equipment Inventory

- The data center intelligent inspection robot can perform automatic inventory of equipment using high-definition cameras.

The robot inspection management platform supports functions such as adding,editing,deleting,batch importing,and exporting equipment.Users can query equipment based on equipment type, model, and usage status. The equipment visual inventory task supports immediate inspection and daily inventory modes, primarily focusing on abnormal movements of equipment. When changes are detected, the robot coordinates with the software platform to promptly issue audible and visual alarms and notify maintenance personnel. Additionally, inventory data reports can be generated